Designed and manufactured to meet or exceed OE specifications, NGK Ignition Coils provide fast response times, stable electrical output, and excellent resistance to heat, vibration, and electrical stress. This ensures smooth engine operation, improved fuel efficiency, reduced emissions, and reliable starting under all driving conditions.

With more than 277 ignition coil part numbers and 90% VIO coverage, NGK is The Ignition Specialist™

The Hidden Enemy: How Flash-Over

Destroys Ignition Coils

Click to read more:

The Effect of Flash-Over on Ignition Coils

When diagnosing misfire codes, it is a mistake to view the ignition coil in isolation. The ignition system—comprised of the coil, boot, and spark plug—functions as a single high-voltage circuit. One leading cause of premature coil failure isn’t usually an internal defect, but a phenomenon known as flash-over.

COP Ignition Systems Have Changed —

Has Your Testing Method?

Click to read more:

Tips and key insights every technician should know when testing Ignition Coil-on-Plug Designs

Troubleshoot – Malfunction

(Code P0351)

When the ignition confirmation signal (IGF) is missing, then the PCM knows that coil didn’t fire. Therefore, a DTC will be set.

Click to read more:

WHO IS THE HEATWAVE?

A new villain ignites beneath the hood. Meet The Heatwave. Armed with relentless temperature spikes, The Heatwave attacks where your engine is most vulnerable — your ignition coils.

WHO IS THE GLACIER?

A Villain that is Silent, Slow and Bitter.

BREATH OF ICE

It starts with a tiny drop of moisture.

BUILT FOR EVERY BATTLE.

The Glacier may freeze the field. But, NGK ignition coils are built to fire when others falter.

THE NGK DIFFERENCE

All NGK ignition coils undergo rigorous testing and quality checks throughout the manufacturing process to ensure proper fit and reliable performance.

Our verification process includes:

-

Validation lab testing certified to ISO 17025 for precise calibration standards

-

Electromagnetic interference testing to ensure the coil does not disrupt other vehicle systems

-

Mechanical vibration testing for durability under real-world conditions

-

Accelerated life testing at elevated voltages and frequencies to identify and eliminate potential failure points

| U6 Type – Rail Coil |

Combines multiple coils into a single assembly. |

| U5 Type – Coil-on-Plug or Pencil Coil |

Provides energy for a single spark plug, requiring as many coils as there are cylinders. |

| U4 Type – Coil-on-Plug with Waste Spark Design |

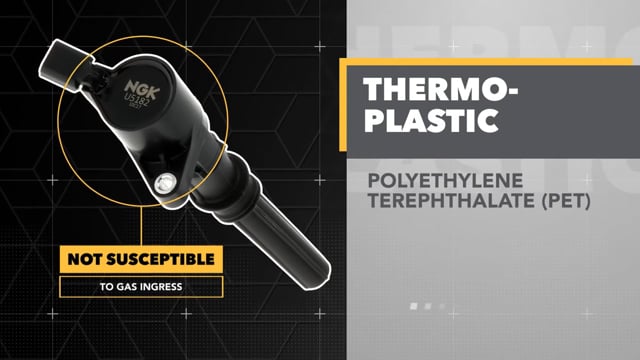

| MOD Performance Ignition Coils |

Next Level Performance |

| U3 Type - Distributorless Ignition System with Waste Spark Design |

Features two high voltage outputs. |

| U2 Type – Distributorless Ignition System |

Include one high-voltage output for each cylinder. |

| U1 Type – Distributor-Based Ignition System |

Ideal for vehicles with a conventional ignition distributor. |